Roller conveyor is the ideal device for highly dynamic applications that require gentle handling of cartons and totes. It provides efficient , top value accumulation, meeting the highest standards. They are most useful for Packaging, Material Handling, Transfers, Assembly and Pallet Handling.

This article takes an in-depth look at roller conveyors.

You learn details on topics such as:

Roller conveyors play a crucial role in material handling systems. They use a sequence of uniformly spaced cylindrical rollers to efficiently transport boxes, materials, objects, and parts over open spaces or between varying elevations. These roller conveyor frames are crafted at a convenient height, facilitating effortless manual loading and unloading. For optimum performance, items transported via roller conveyors should possess firm, flat surfaces to glide smoothly over the rollers.

These conveyors offer great versatility, being employed in a range of applications such as accumulation, inertia reduction, and swift sorting of products. Driven roller conveyors have rollers connected to a motor through mechanisms like chains, shafts, or belts, which control the consistent movement speed of items. These systems can be bi-directional, allowing for reversible movement and transport of products between different levels, with the motor capable of changing the direction of the items being moved.

Chapter 2: How is a roller conveyor constructed?Roller conveyors are designed with specific features to meet the needs of various applications. While roller conveyors can differ in structure, mode of movement, and manufacturer-specific features, they share several fundamental characteristics.

Powered roller conveyors utilize small belts and plastic spools to provide traction to the rollers. Friction belts or chains positioned beneath the conveyor drive the heavy-duty rollers. These belts or chains are connected to a shaft that runs the length of the conveyor's frame and is linked to an electric motor, which powers the rollers.

RollersRollers for roller conveyors are metal cylinders fitted into its frame with sets of bearings on either end of the cylinder. There are several types of conveyor rollers each of which is designed to fit the needs of the product being transported. Rubber and plastic rollers increase friction while steel and aluminum rollers have a smooth surface. Rollers are selected for their ability to keep products on the conveyor, and their ability to maintain the integrity of products.

Plastic RollersPlastic conveyor rollers are cost-effective and designed for handling light loads. They are easy to install and require minimal maintenance. Plastic rollers comply with the noise standards set by the Occupational Safety and Health Administration (OSHA). Due to their resistance to corrosion, rust, and moisture, plastic rollers have a longer useful life. They are also easy to clean, making them ideal for transporting food packaging in the food industry.

Nylon RollersNylon rollers are designed for medium to heavy loads, offering durability and strength for constant use. Made from synthetic polymers, they are resistant to abrasion, chemicals, and corrosion. Like plastic rollers, nylon conveyor rollers are lightweight, easy to install, and produce minimal noise due to their low vibration.

Rubber-coated rollers feature a layer of rubber placed over steel, stainless steel, or solid plastic rollers. This rubber coating enhances grip and provides protection for both the roller and the products being transported. The type of rubber coating varies based on industry requirements. Rubber-coated rollers are resilient, soft, and capable of gripping smooth materials effectively.

Rubber-coated rollers are anti-static, chemical-resistant, customizable, and durable. They are commonly used in industries such as automotive, printing, packaging, and fabrication. The increased friction provided by the rubber coating helps prevent slippage between the roller and materials.

Steel and Stainless Steel RollersSteel and stainless steel rollers are among the most popular materials for conveyor rollers due to their durability and smooth surface. They are easy to clean, long-lasting, and strong enough to handle heavy materials. Steel and stainless steel rollers often serve as the core for plastic, nylon, and rubber rollers due to their exceptional strength and smooth surface.

Stainless steel rollers are versatile and compatible with various materials. They can accommodate smaller diameters, feature precision bearings or fixed shafts, and can be adjusted to meet specific shipping and operational needs.

Structure of a Roller ConveyorThe frames of roller conveyors can be either permanently installed or temporarily positioned and are typically made from steel, stainless steel, or aluminum. Temporary roller conveyors offer the flexibility to be assembled, disassembled, and repositioned as needed. Among the structural metals used, aluminum is lighter and ideal for handling lighter loads.

Support legs for roller conveyors come in various sizes, materials, and styles to match the specific requirements of the conveyor and its loads. They may feature a tripod or "H" design, with "H" design legs categorized into light duty, medium duty, and heavy duty. These support legs are constructed from channel material and are designed to accommodate rollers of different diameters.

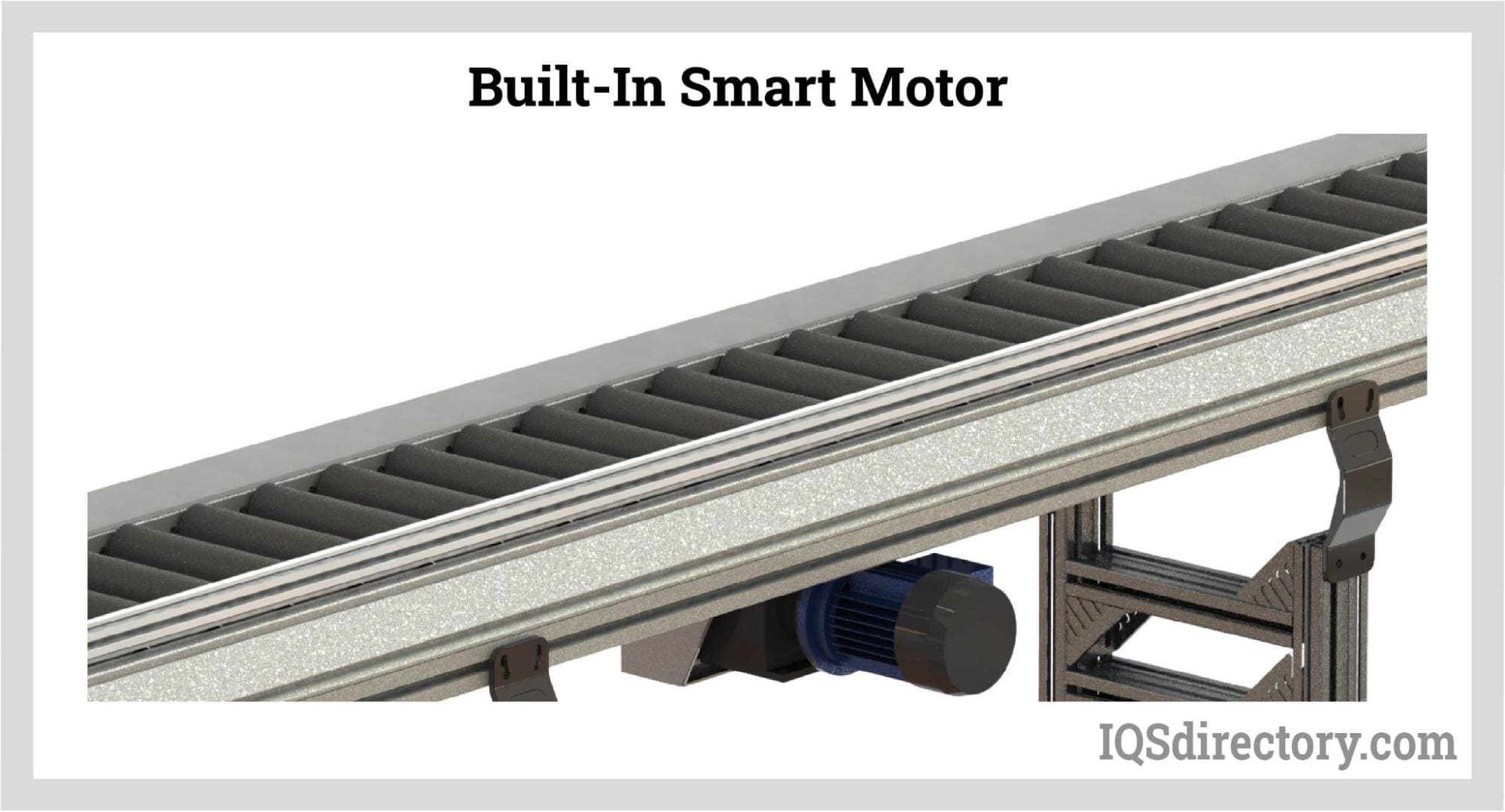

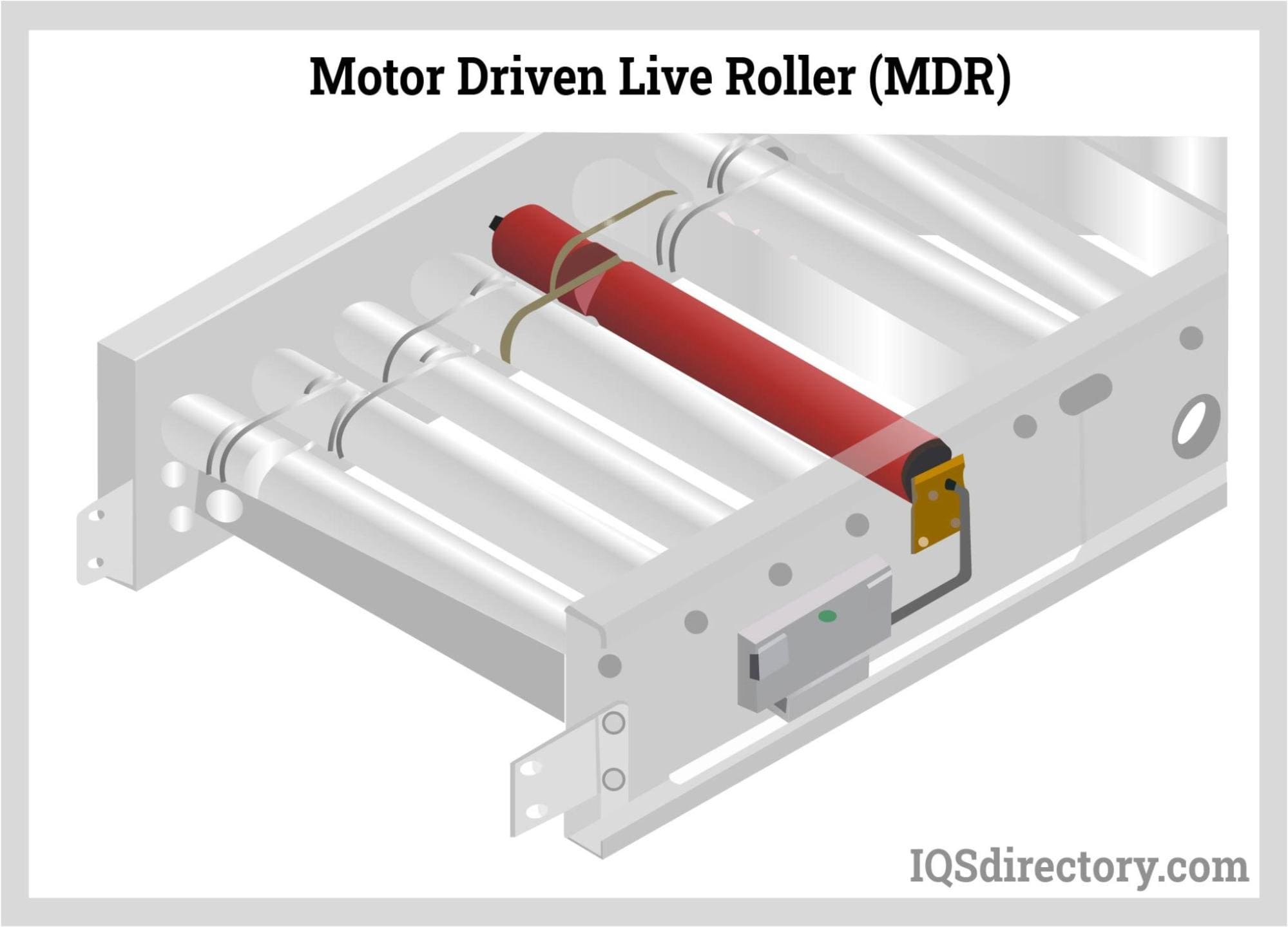

Roller conveyor motors are typically 24-volt DC motors, which are energy-efficient and produce less torque, enhancing safety. In a motorized roller conveyor system, the conveyor is divided into zones, with each zone equipped with a motor-driven roller (MDR). These motors are integrated into the rollers within each zone and are controlled by an operator who adjusts the speed and direction of the conveyor's movement.

Non-precision bearings, such as sleeve bearings and bushings, have looser tolerances and lower accuracy compared to precision bearings. They are typically made from the same materials as precision bearings but are designed for smaller loads and lower speeds. The term "non-precision" indicates that these bearings do not require the high accuracy and tight tolerances of precision bearings. They are commonly used in applications where precise performance is not critical.

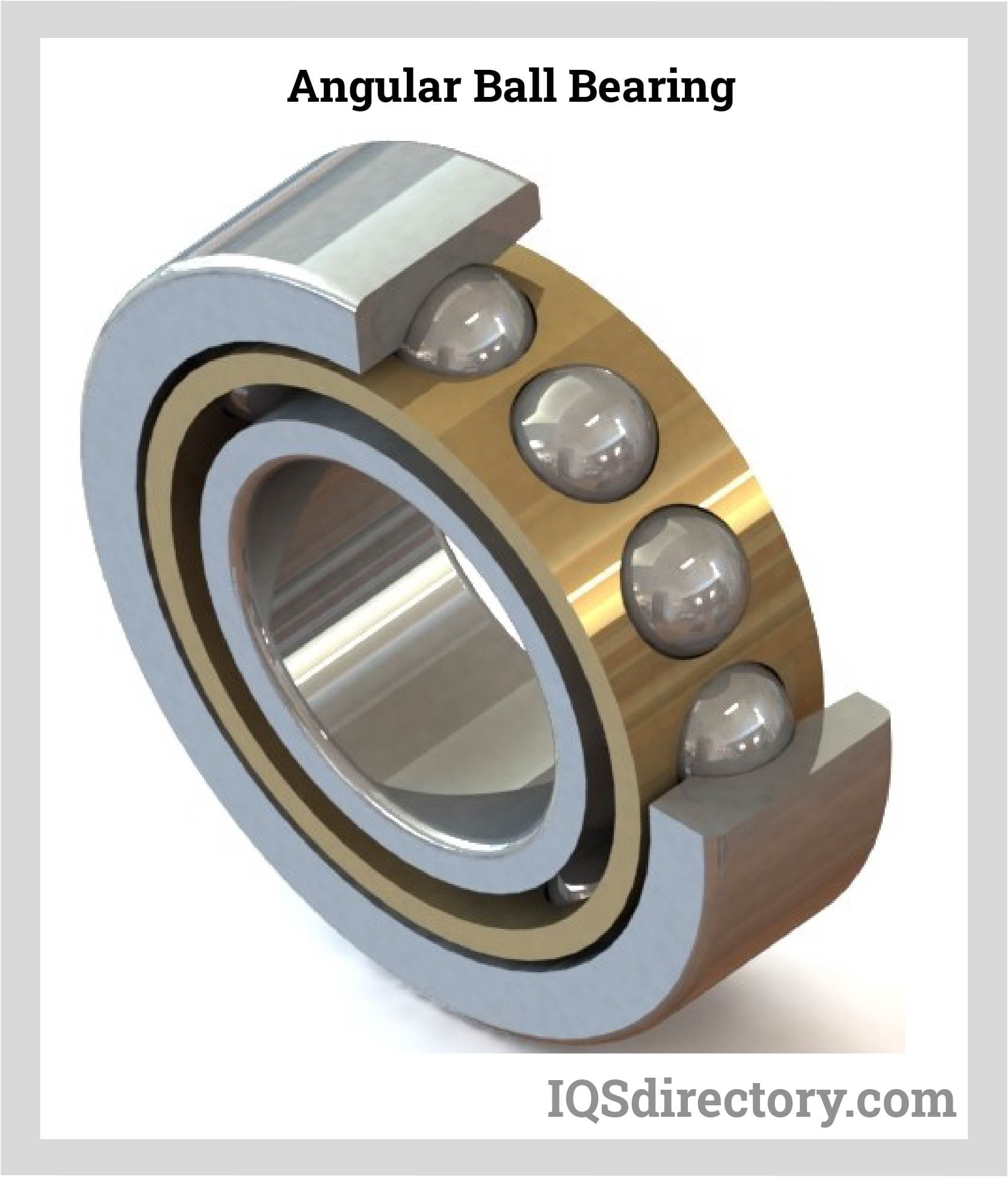

Angular Contact Ball BearingsAngular contact ball bearings are designed to handle combined radial and axial loads by making contact with the line of action of the load at an angle. The inner and outer ring raceways of these bearings are positioned close to each other in the direction of the bearing axis, allowing them to manage both radial and axial forces effectively. There are several types of angular contact ball bearings, including single row, double row, and four-point contact bearings, each suited for different applications based on their load-handling capabilities.

In motorized roller conveyors, angular contact ball bearings are crucial for supporting the conveyor's line shaft, which is a long, rotating cylinder linked to the rollers through belts and drive spools. When the shaft is activated, it powers the rollers to move the materials. The combination of angular contact ball bearings, the shaft, belts, and drive spools ensures smooth and efficient operation of the conveyor system, reducing noise and increasing performance.

Pillow Block BearingPillow block bearing, also known as plummer block bearing, are means for supporting the shaft. They are commonly used with conveyor systems and have a single bearing that is mounted parallel to the conveyor. Pillow block bearings have a mounting block that houses the bearing and is bolted to a support surface.

Pillow block bearings are designed to manage misalignments and shaft deflections. They are commonly utilized for their capacity to support both axial and radial loads effectively.

Roller Conveyor SprocketsRoller conveyor sprockets are specialized gears that engage with conveyor chains to drive the rollers on a powered conveyor system. These sprockets come in various sizes, which are determined by factors such as the number of teeth, power requirements, diameter, and bore length. Sprockets may feature plastic hubs suitable for light to medium loads, while steel hubs offer greater strength for handling heavier loads.

Roller Conveyor CurvesRoller conveyor curves are integral to a conveyor system, allowing for changes in direction and flow of materials while maintaining their orientation. These curves are engineered to navigate around corners, bends, and obstacles. The design of the curve is influenced by its angle, which typically ranges from 30° to 90°, with angles exceeding 90° requiring specialized engineering solutions.

Rollers for roller conveyor curves are conical or cylindrical shaped to be able to adjust the radius of the curve. They are designed to handle cardboard boxes, plastic crates, tires, and lightweight items. Roller conveyor curves are adjusted for the size and weight of the goods being transported and have support rollers on their frame.

Roller conveyor curves may include additional features such as side guides, which can be either fixed or adjustable. While traditional roller conveyor curves are single curves, S-shaped designs are used to save floor space. Spiral roller conveyors, which transition from one level to another, are employed in systems with limited space. Other variations include split, multi-track, and double-deck curves.

Chapter 3: What are the different types of roller conveyors?Roller conveyors come in various forms, primarily categorized into powered (motor-driven) and gravity roller conveyors. Gravity roller conveyors represent the most basic type, where products are moved manually along the rollers. In contrast, powered roller conveyors include several types, each equipped with different power systems to drive the rollers.

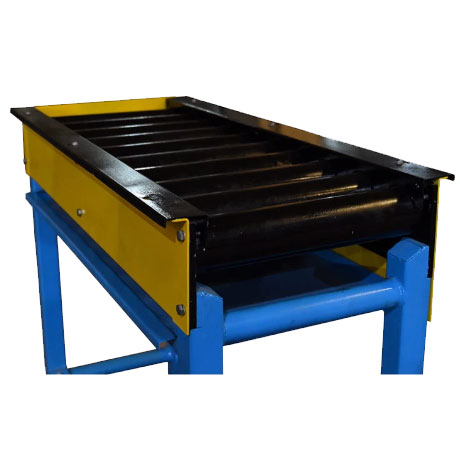

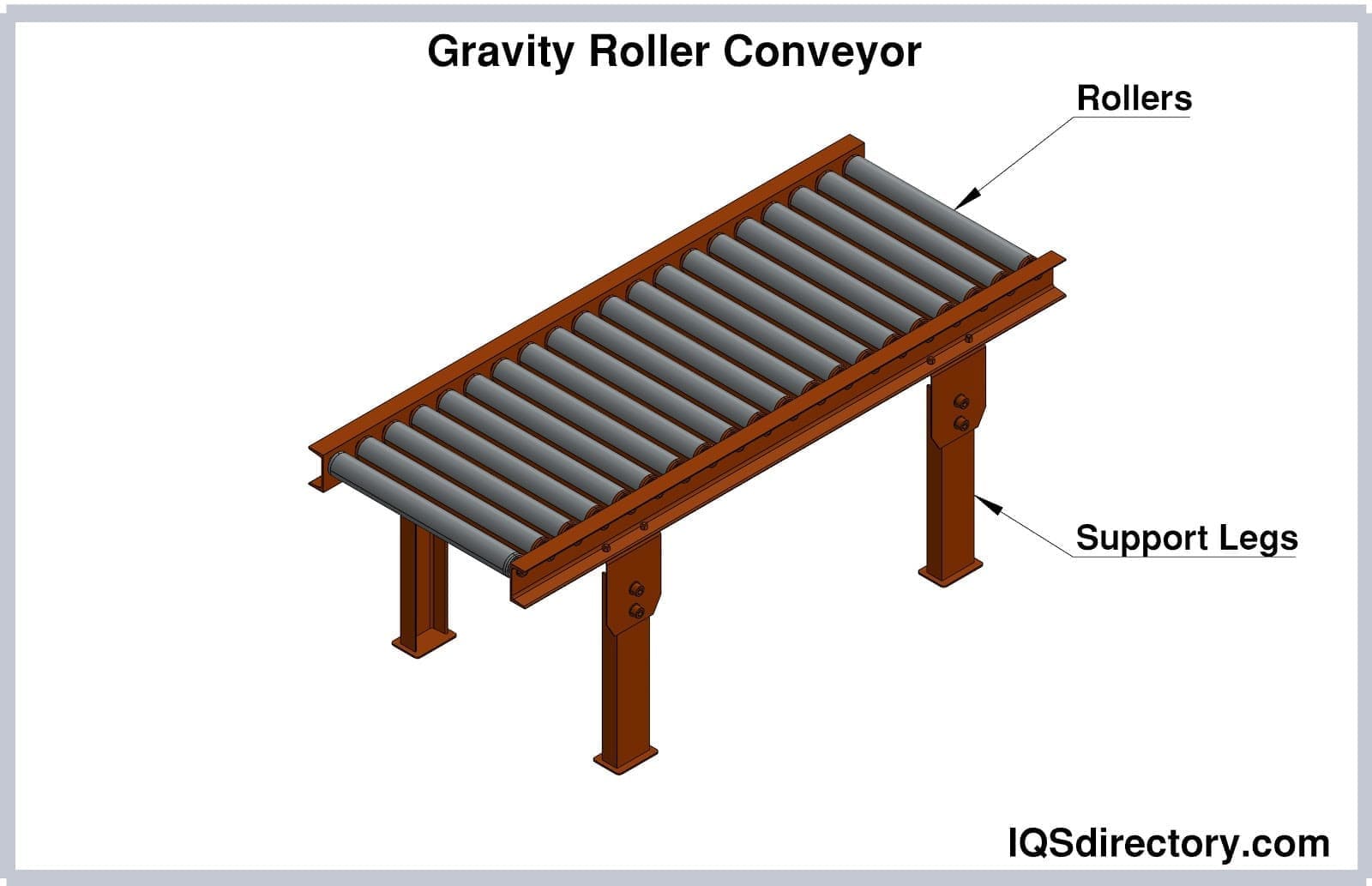

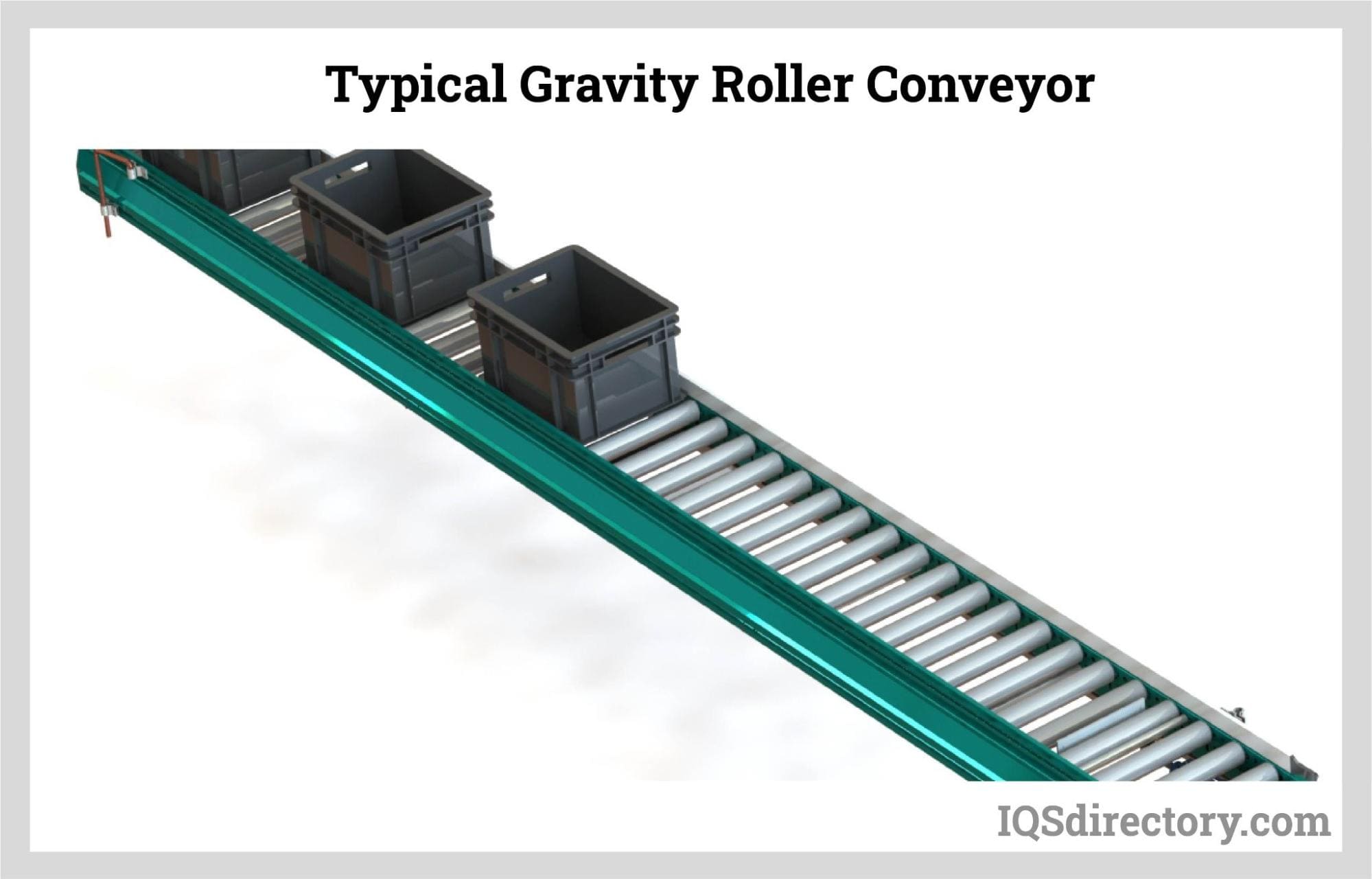

Gravity Roller ConveyorGravity roller conveyors are the simplest type of roller conveyor, featuring a frame with rotating rollers and support legs, relying solely on gravity to move materials. They are designed for transporting light to medium weight loads and are cost-effective due to the absence of a motor.

Gravity roller conveyors are constructed from materials like steel, aluminum, and plastic. They may include components such as curves, slide rails, supports, hanging brackets, sensors, and pop-up stops. These conveyors are often used as temporary setups or as substitutes for skate wheel conveyors in heavy-duty applications where precise scheduling of stacked loads is not required. A notable advantage of gravity roller conveyors is their flexibility in positioning during loading and unloading, enhancing efficiency and reducing processing time.

Belt Driven Live Roller Conveyor (BDLR)Belt-driven live roller conveyors utilize a motor to power each roller via a motorized belt, enabling precise control over material movement. This setup allows for halting, turning, side unloading, sliding, and reversing of loads. The motor-driven belts facilitate the vertical movement of materials and maneuverability around curves. Some models include a shaft positioned perpendicular to the rollers, which adjusts and drives the belts that power the rollers.

Certain belt-driven live roller conveyors feature rollers positioned higher than the frame to accommodate goods wider than the conveyor itself. BDLR conveyors are suitable for transporting clean and dry medium to heavy loads and offer the ability to pause or reverse the flow of materials.

Chain Driven Roller ConveyorChain-driven roller conveyors use a chain drive system connected to each roller. Unlike single chain-driven conveyors that use one long chain to power all rollers, these conveyors have sprockets attached to each roller to drive and rotate them individually.

Chain-driven roller conveyors offer high power transfer, making them ideal for handling medium to heavy loads. They can also reverse direction, enabling bidirectional material movement.

These conveyors are used in applications such as palletizing, filling, load staging, and strapping. Although not as powerful as roll-to-roll powered conveyors, chain-driven roller conveyors are known for their durability and excellent performance in demanding and hazardous environments.

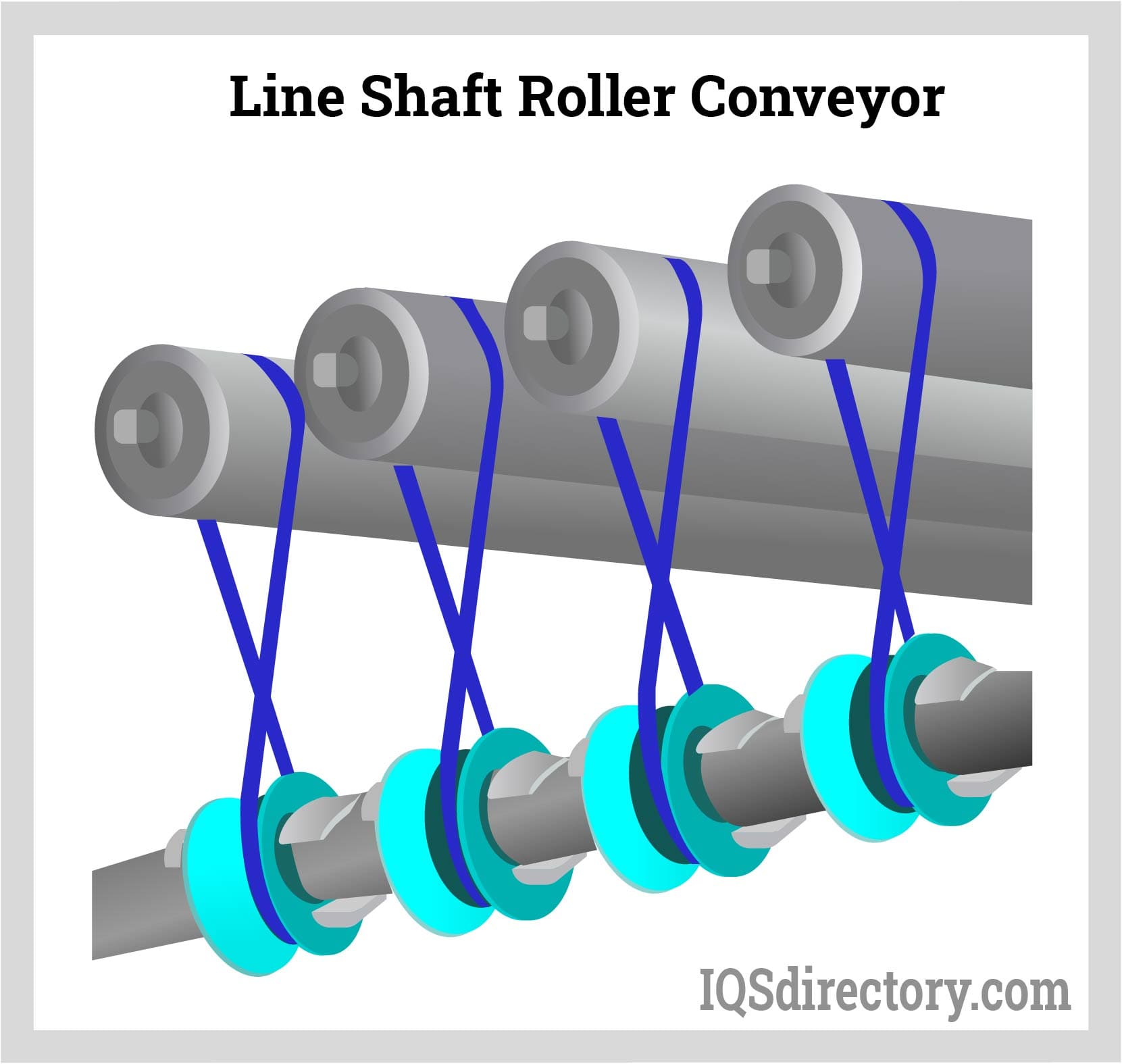

Line shaft roller conveyors utilize a rotating shaft connected to the rollers through drive spools and belts. Each roller is linked to the shaft via its own spool and belt. When the shaft is activated, it drives the belts, which in turn rotate the spools and rollers.

An electric motor, regulated by a programmable logic controller (PLC), powers the shaft. This design eliminates the need for chains and sprockets, resulting in a quiet and smooth operation. The shaft extends along the conveyor and is positioned beneath the rollers on one side of the frame.

A single line shaft can drive more than 100 feet of both straight and curved rollers, enhancing the efficiency of the conveyor system. These conveyors are ideal for tasks such as accumulation, sorting, managing low back pressure, and handling medium to light loads.

Line shaft roller conveyors are not recommended for use in harsh or hostile environments. They should be avoided in wet or oily conditions, at slow speeds, or on inclined surfaces. It's important that the materials being conveyed maintain contact with at least three rollers at all times.

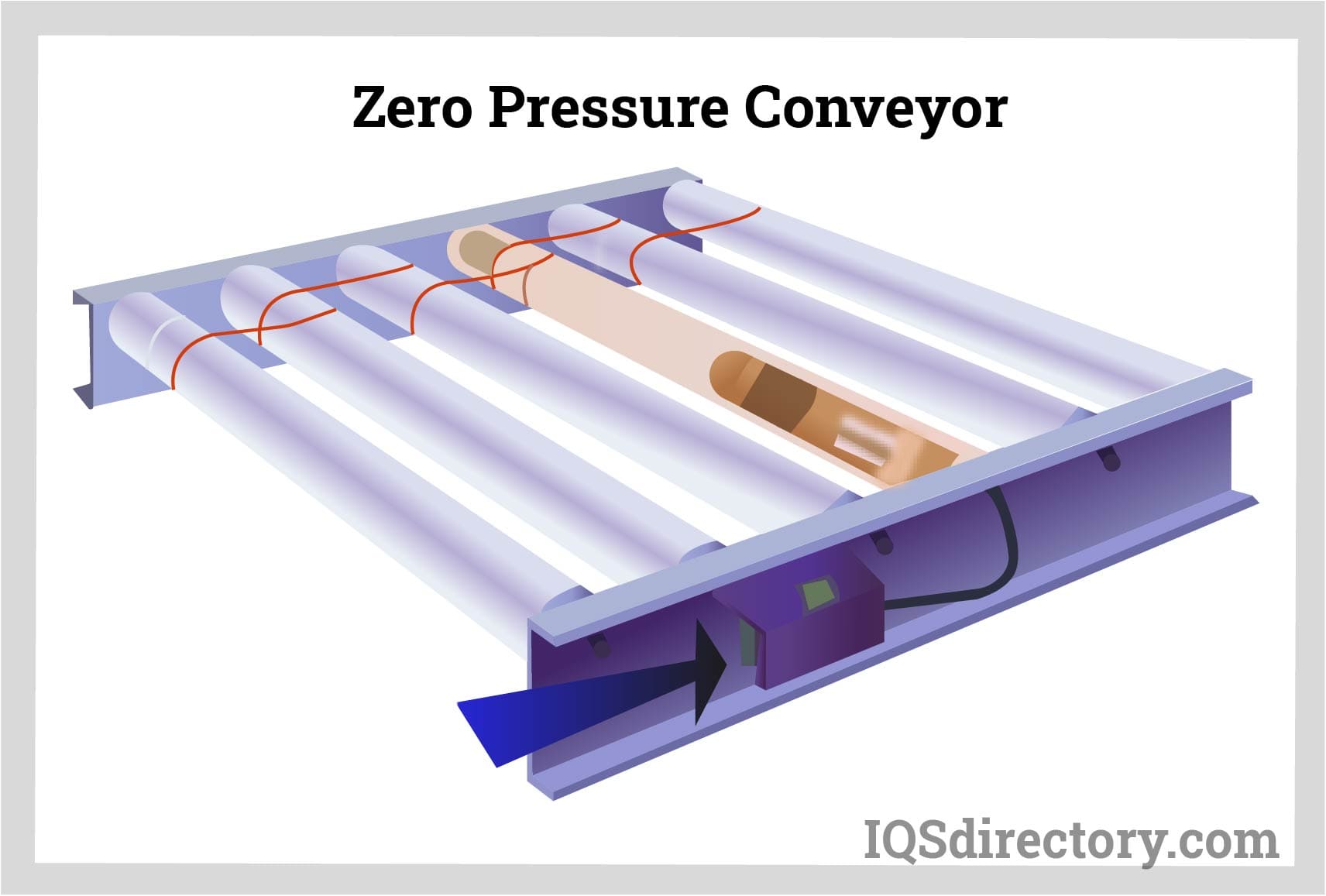

Zero Pressure Roller ConveyorTraditional accumulation conveyor systems allow materials to collide and pile up, creating pressure that can compromise product quality. These systems lack control over material movement, causing them to continue operating even when products are stationary and stacked.

Zero pressure roller conveyors, also known as pressureless accumulating conveyors, use 24-volt DC motors to drive individual zones, with control managed by photoelectric sensors. These sensors send information to a central controller, which monitors the status of the zones. If a zone ahead contains items, the controller halts movement to avoid accumulating back pressure.

Each zone of a zone pressure roller conveyor has a powered roller, sensor, and three or four slave rollers. The powered roller is connected to the controller, which determines when products can leave or enter the zone. The rollers are powered by an internal motor linked to non-powered slave rollers by O-rings.

Zero pressure roller conveyors can be purchased as kits designed to retrofit older conveyor systems, and they are ideal for automation tasks that demand precise timing, speed control, and consistency. Although they are more complex and involve electronic components compared to older models, they offer improved efficiency, better material flow regulation, and a smoother transfer of goods.

Motor Driven Live Roller (MDR)Motor-driven live roller conveyors feature transportation rollers equipped with small 24-volt DC motors integrated into each roller. The system is segmented into zones, each comprising a motorized roller and three or four additional rollers driven by the motor. These zones function as accumulation areas. Photoelectric sensors, along with controller cards, manage the flow of products and the operation of the roller motors.

Motor-driven roller conveyors are well-suited for accumulation tasks due to their compact design. They simplify the system by removing the need for PLCs or complex pneumatic setups. The conveyor's transportation rollers are driven by bands that can be easily replaced. To accommodate declines, inclines, or variations in speed, belts are used in conjunction with the MDR rollers.

Merge Roller ConveyorsMerge roller conveyors, also known as combiner roller conveyors, are designed to gather products from multiple incoming lines into a single stream. Typically used for consolidating products from upstream sources, these conveyors handle light to medium loads and can merge two to four lines. Their design incorporates either fixed or powered rollers to facilitate the combination of incoming product flows.

The primary advantage of merge roller conveyors is their ability to reduce manual handling of products while efficiently integrating upstream and downstream processes. They enhance warehouse flow and decrease the need for labor in product placement and movement. Additionally, merge roller conveyors can be easily repositioned and adjusted to accommodate changing needs.

Chapter 4: What are the applications for roller conveyors?Since their debut in 1908, roller conveyors have become crucial in product handling, assembly, and supply chain management. These conveyors are versatile and can manage loads of various sizes. Over time, their designs and functions have evolved significantly, with continual innovations and improvements being introduced.

Roller conveyors are used for a variety of applications, including:

Each application for roller conveyors requires a bespoke design tailored to specific needs. For optimal performance, a roller conveyor must be engineered to fit its intended environment. Custom roller conveyors often include modular components like straight sections, curves, transitions, mergers, power types, and separators. Every aspect must be carefully integrated into a cohesive system.

Designing a custom roller conveyor presents challenges, such as deciding whether the system will operate as a standalone unit or be part of a more complex setup with interconnected components. It’s also essential to determine the type of power used—whether chain, belt, or roller—based on system requirements.

Airport Roller ConveyorsRoller conveyors play a critical role in airports, including applications like check-in counters, baggage handling systems, and loading areas. Depending on the handling requirements, both gravity and powered roller conveyors are utilized to manage different types of baggage and packages.

Assembly Roller ConveyorsIn assembly settings, roller conveyors come in various forms such as overhead, belt, and traditional roller types. While conveyor systems can sometimes be noisy and disruptive, roller conveyors are preferred for their reliability, durability, and quieter operation, which enhances worker comfort.

Supply Chain Roller ConveyorsIn supply chain and warehouse operations, roller conveyors offer a cost-effective alternative to forklifts for product movement. They simplify logistics by reducing manual handling, speeding up product flow, and easing the workload on workers.

Packaging Roller ConveyorsThe packaging industry relies heavily on roller conveyors for moving, stacking, and sorting packages. Depending on the specific requirements, either gravity-fed or powered roller conveyors are employed to facilitate efficient package processing.

Food and Beverage Roller ConveyorsDesigning roller conveyors for the food and beverage sector is complex due to stringent industry regulations and standards. These conveyors must meet high cleanliness and hygiene standards to be suitable for use in food and beverage applications.

Metal Working Roller ConveyorsIn metalworking, roller conveyors are primarily used for sorting and identifying scrap materials. Their robust construction and adaptability make them well-suited for handling heavy loads and various metalworking processes.

The industries mentioned above are just a few examples of how roller conveyors are integral to diverse sectors. From automotive manufacturing to robotics, roller conveyors are crucial for efficient product handling and movement.